Ingersoll Rand QX Wrench - First time use

TLDR; The initial use of the wrench should involve setting up the torque and angle values beforehand using the INSIGHTConnect app to ensure optimal performance. These configurations are adjustable and can be modified at a later time.

Quick starter guide to set up the wrench using the INSIGHTConnect app

Download the INSIGHTConnect app. The app is used for setting up the wrench at the beginning.

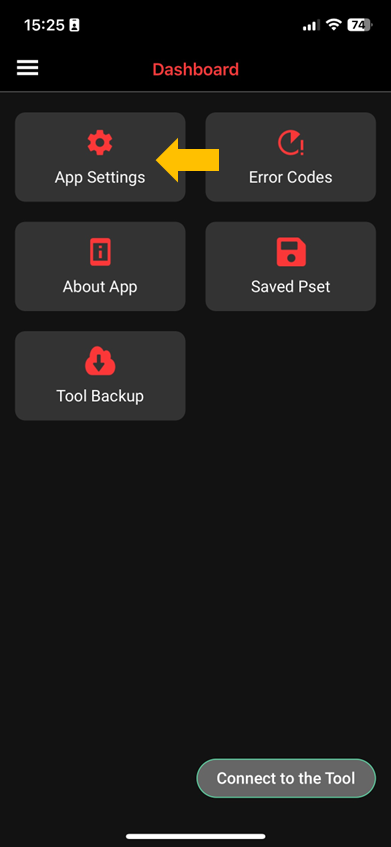

Tip: You can change the language via the app setting

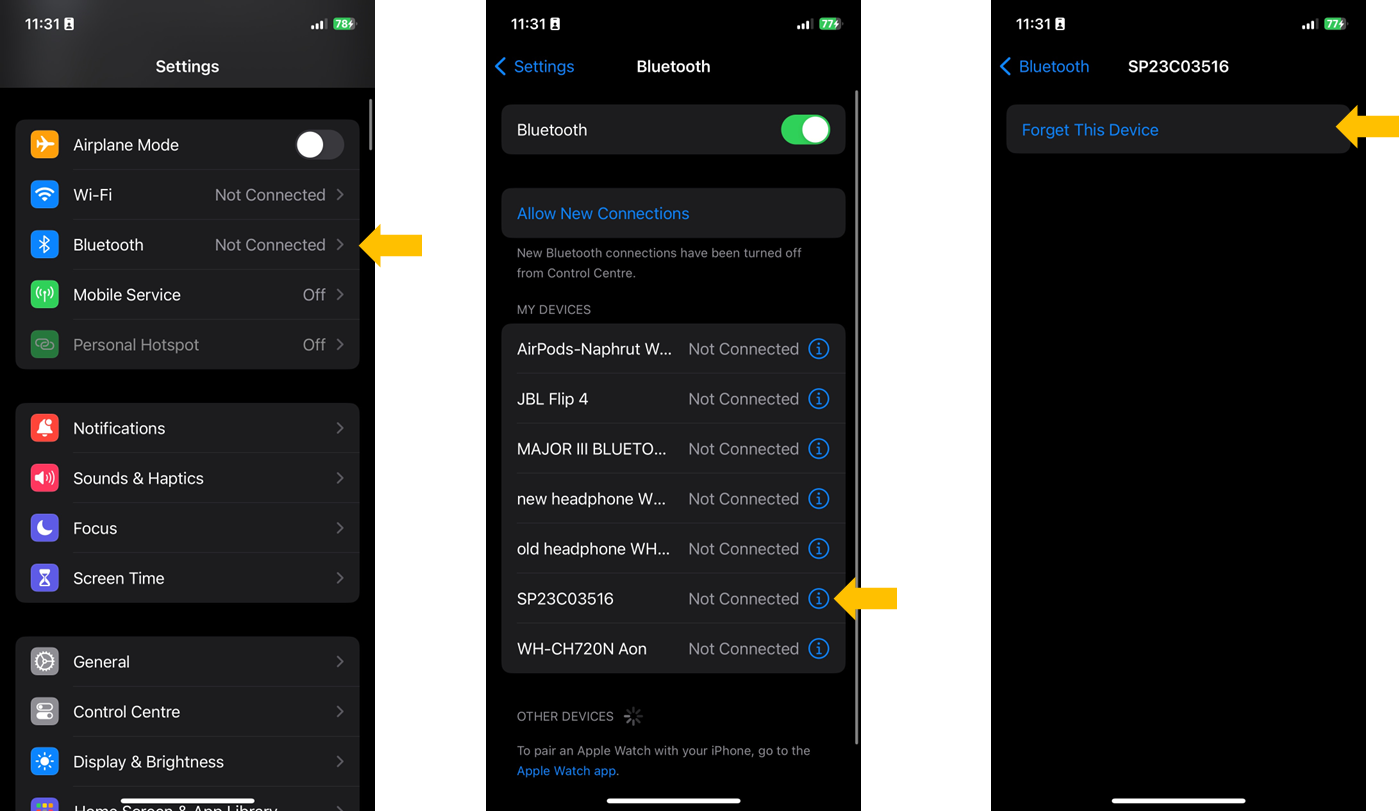

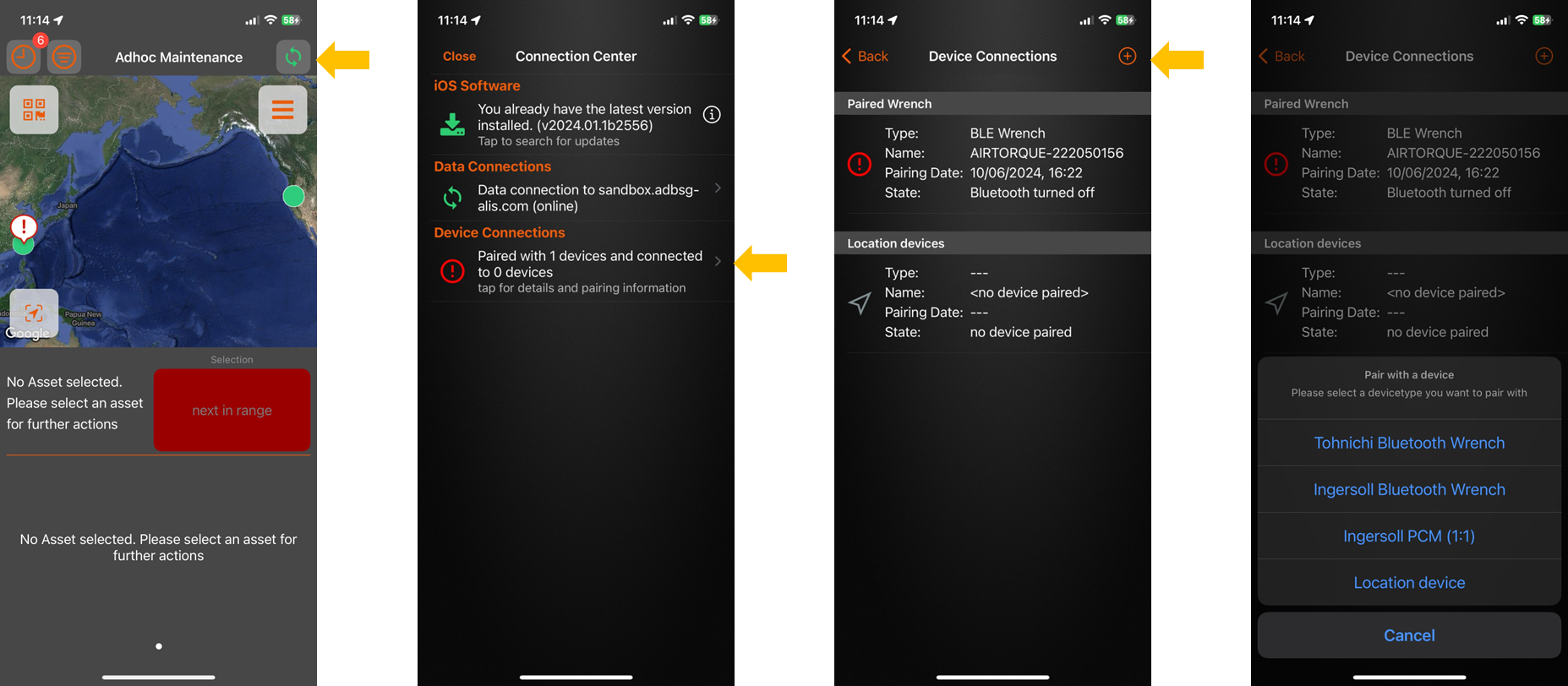

Connect the wrench to the app

Wrench: plug the battery into the wrench. Once it starts up, choose the app pairing mode.

INSIGHTConnect app: open the app on your phone, click on ‘Connect to the tool’, and follow the screen

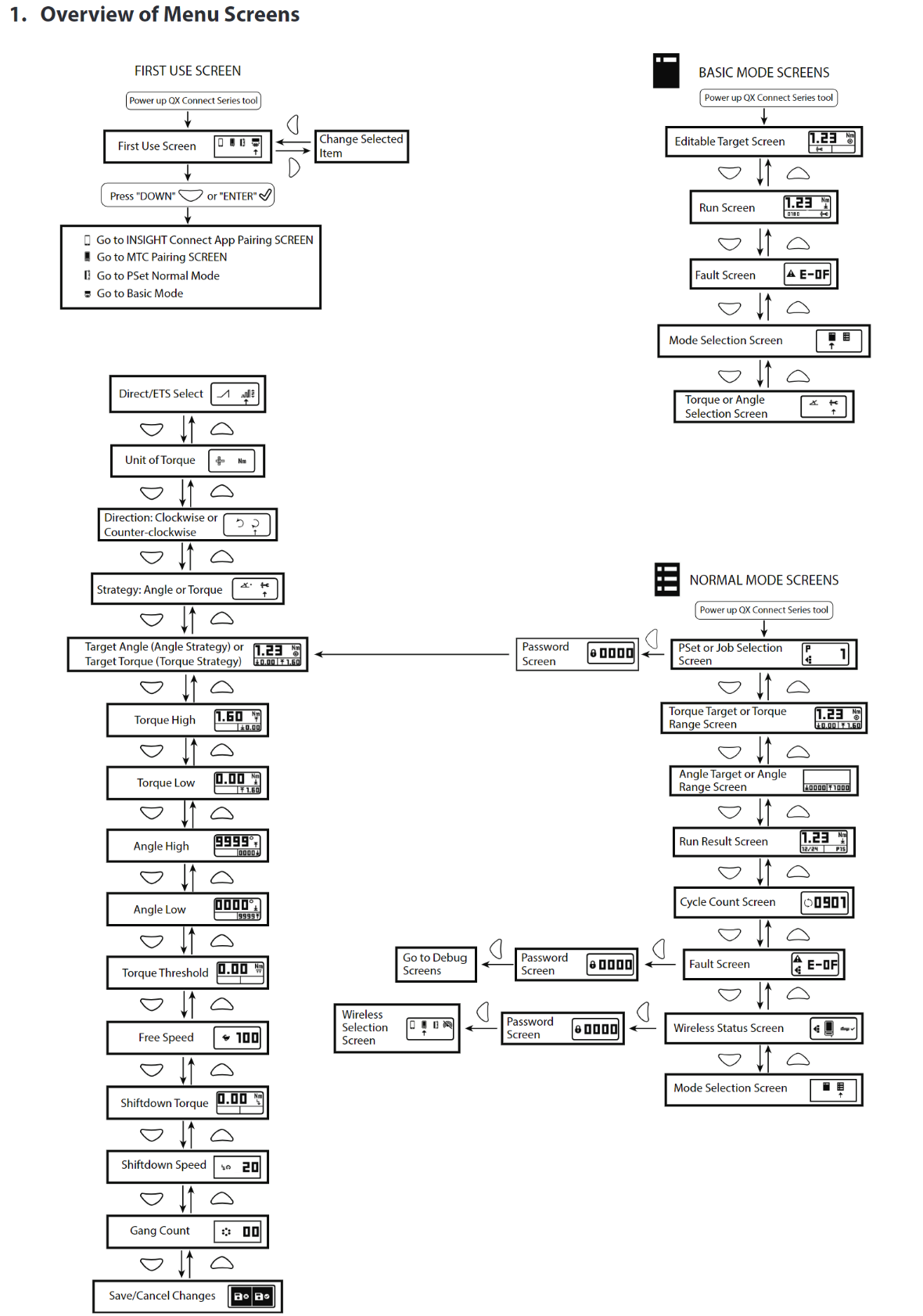

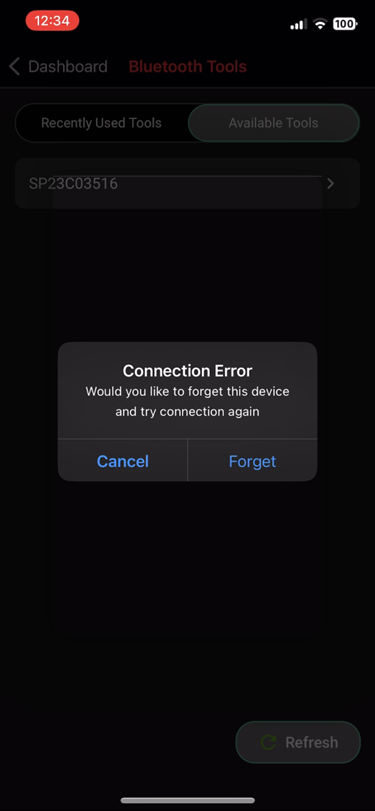

Remark: if you find that the wrench has some problems with the connection, you can try to reset it to factory.

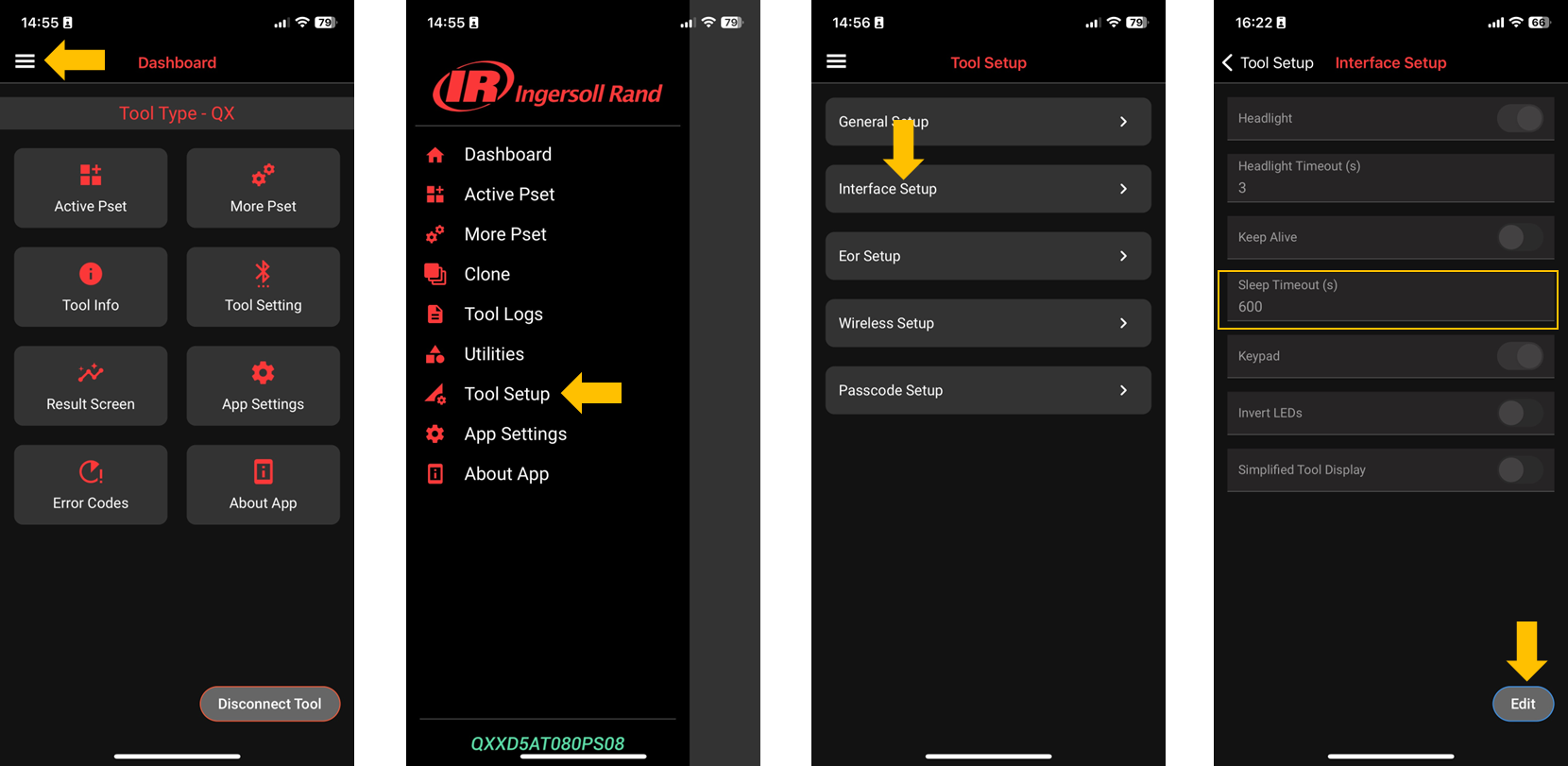

By default, the app and the phone will be disconnected after 60 seconds (sleep timeout). It is recommended that you change this setting, so you have more time to set up the wrench.

Go to the 3 lines → Tool Setup → Interface Setup → Edit → Sleep Timeout (s)

Recommendation: set it to 600seconds (10 minutes) or less to avoid overheating

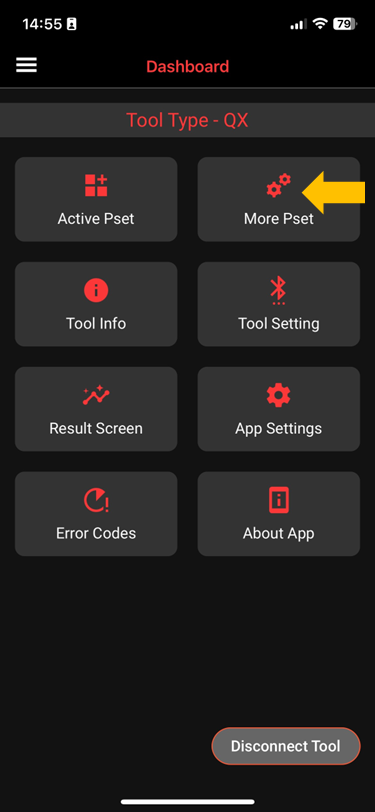

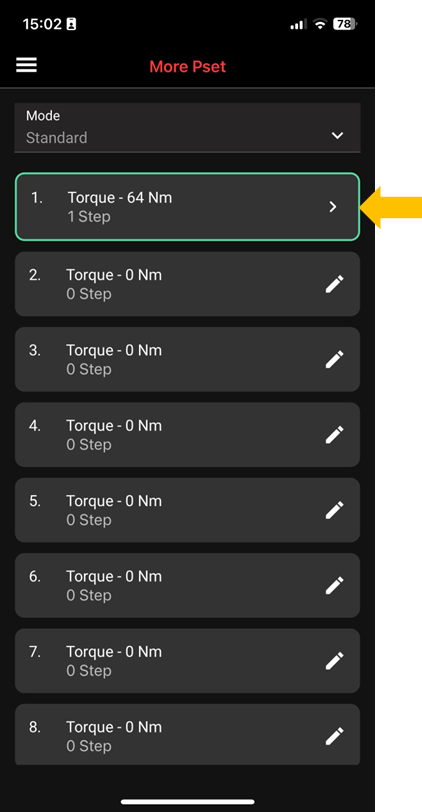

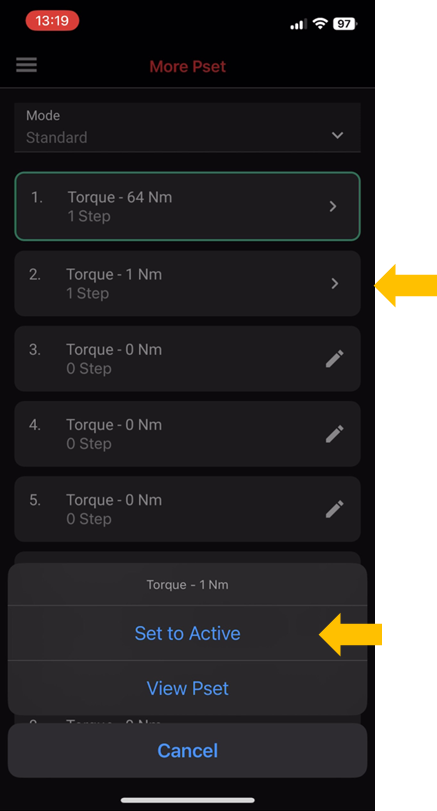

Go back to the dashboard and click ‘More Pset’; this is where you can pre-program the wrench. You can edit or add them (up to 38 psets).

“Standard mode” (NOT Basic)

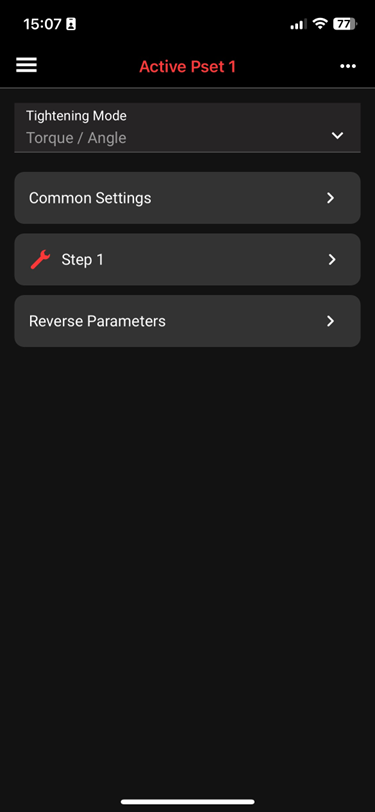

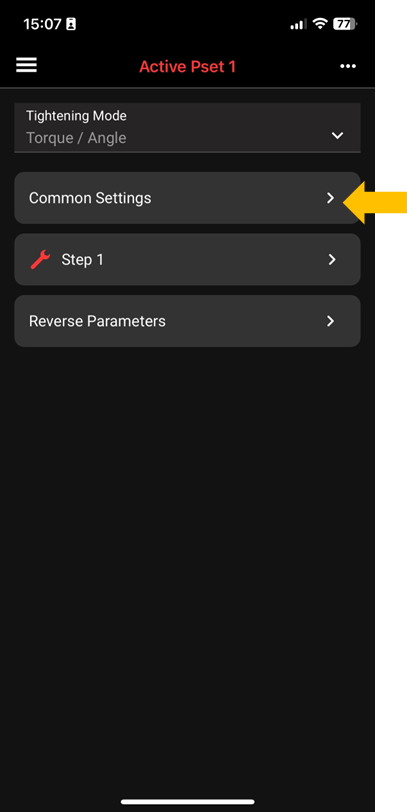

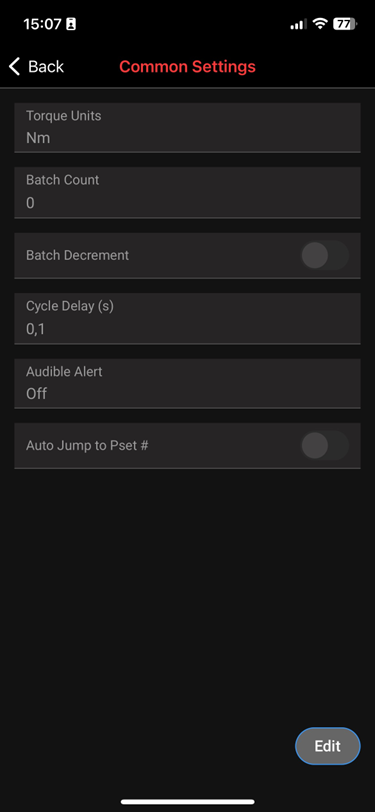

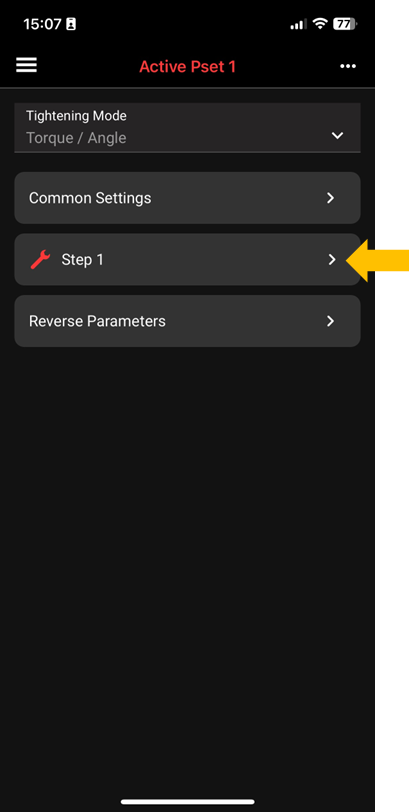

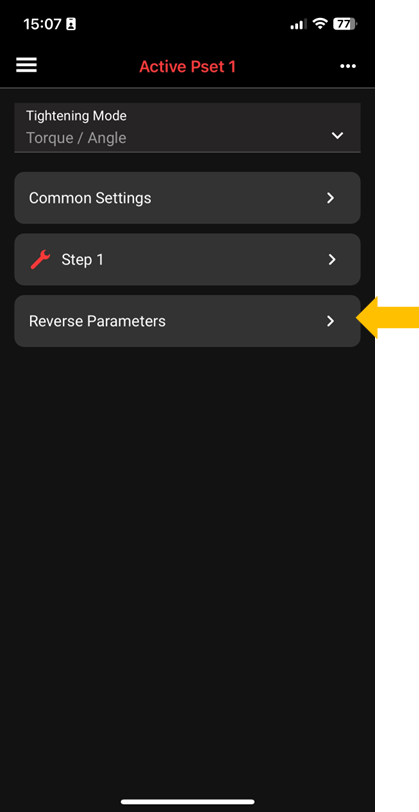

Change the common setting, Step, Reverse Parameters

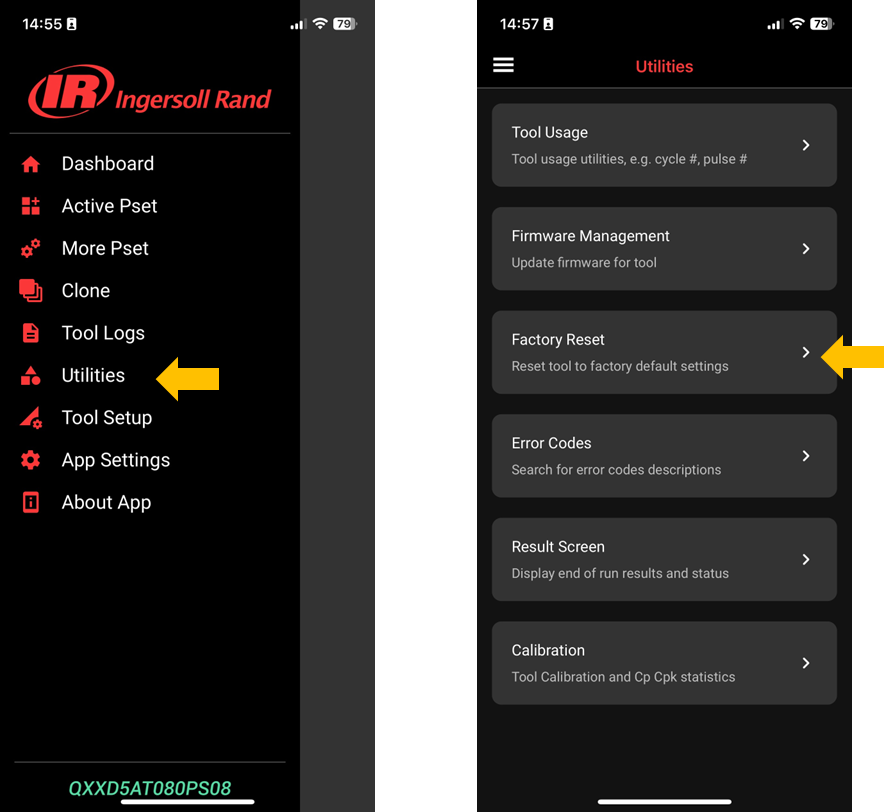

Example for 40 Nm (Reliance Base)

Example 25 Nm (Eurobase)

We suggest the following settings overall (normal and reverse) .

Acceleration to be 30%

Free speed to be about 20% (75 RPM ) (do not exceed 150RPM)

Shift down point to be about 25% of target torque

Shift down speed to be 10% (35 RPM)

If you have an “ETS” wrench we find “performance” to be the best result

![]() Example Config that can be loaded through the Ingersoll App :

Example Config that can be loaded through the Ingersoll App :

40 Nm

QXX-SP23L-05142510 BRU 1-step.cfg

25 Nm : QXX-SP24F-051425153024 1 step 25 Nm.cfg

Changing to different psets

You might want to have different psets if you have different bases that require different torque values. From the app, you can edit/add a new pset. In total, you can have up to 32 psets.

Change active pset from the app:

Pro tip: doing this on-site might not be convenience, try changing the pset directly from the wrench!

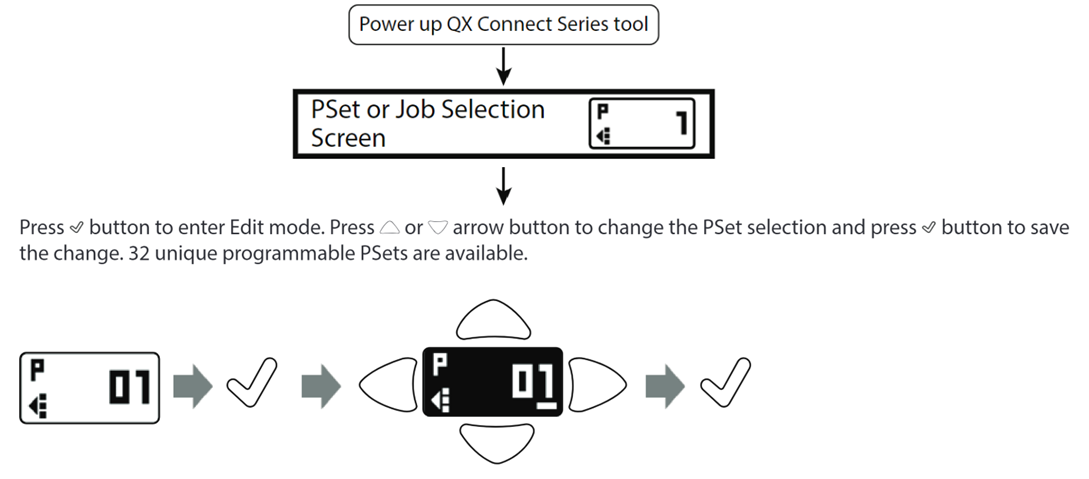

Change active pset on the wrench:

By default, the wrench will make pset1 active.

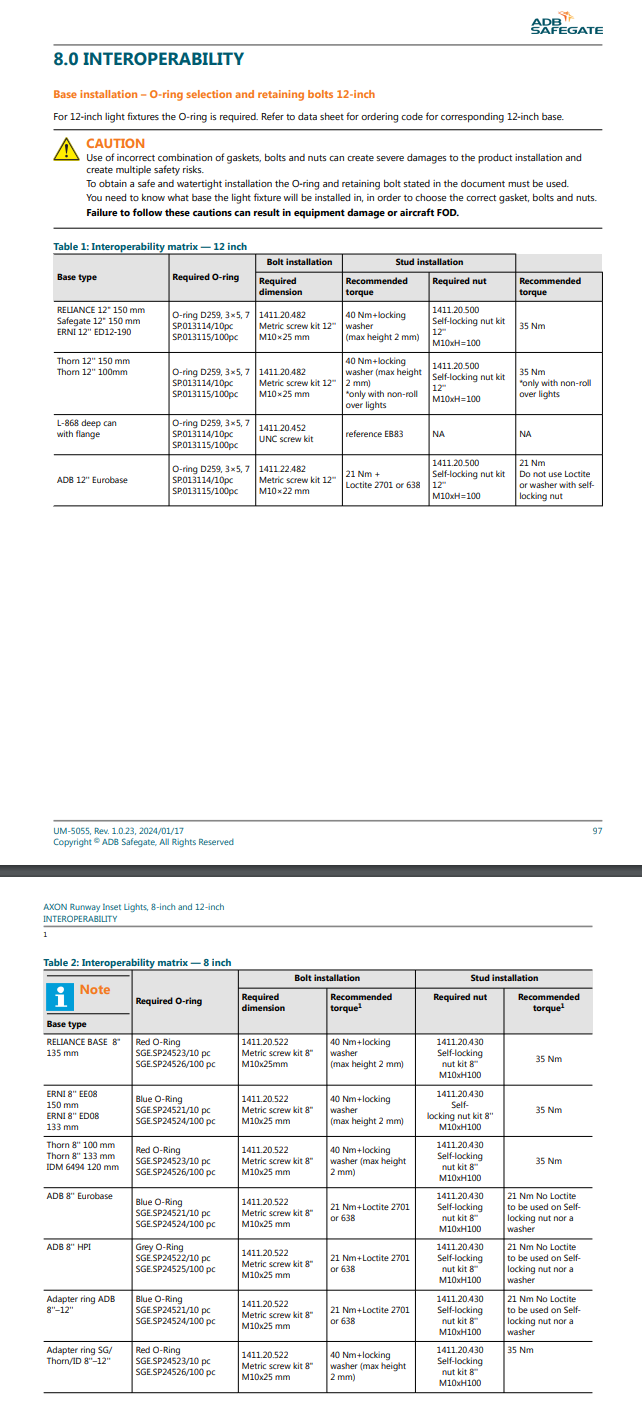

To change to different psets from the wrench, you have to navigate to this screen. (Tip: you can use the up-down buttons to get to this screen, see FAQ for more screen explanation)

Go to the ALIS Web Application and go to Settings > Maintenance Torque Settings

* Set your LOW Default and HIGH Limits similar as in the wrench

* Optional - Set/Modify your Initial torque conditions as in How-to Determine the initial torque categoriesYou can now connect the wrench to the ALIS app and start your torque maintenance.

![]() Remark: ALIS and the INSIGHTConnect app cannot be used at the same time

Remark: ALIS and the INSIGHTConnect app cannot be used at the same time

→ Ingersoll Wrench

→ Ingersoll Wrench