How-to Determine the initial torque categories

TLDR ; You can do a test by torquing a bolts to the different fixation conditions you want to have and read the angle of the wrench result to know how in which range you need to configure your “Tight / Loose / Very Loose” angles. This is only for the Ingersoll Rand QX wrench and the results vary depending on the airports use of bolts, washers & bases.

Introduction

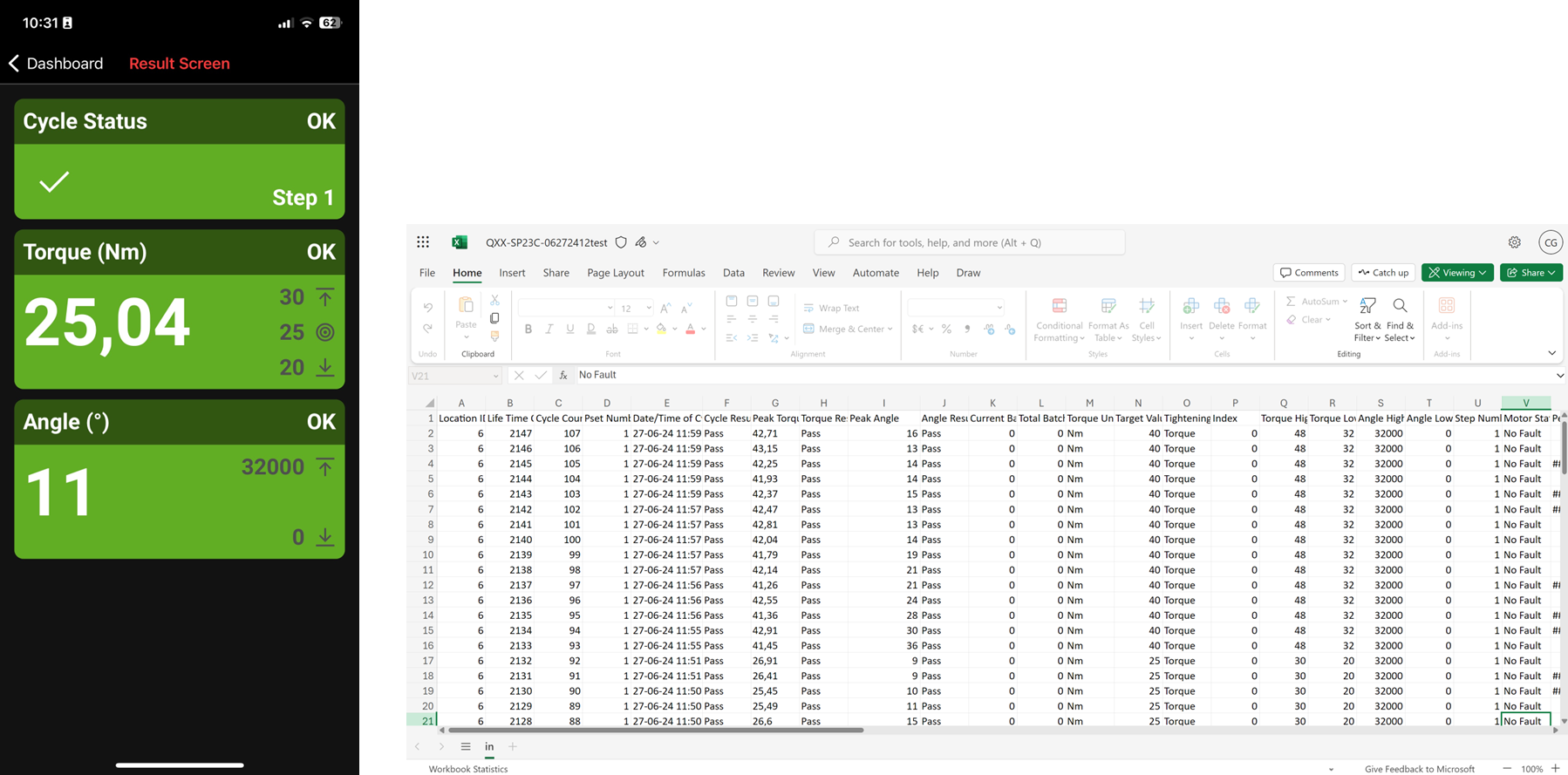

One of the torque maintenance analysis is looking at the initial torque conditions. The Ingersoll Rand ALIS-compatible wrenches have the ability to measure the angle of rotation which can be used to determine the condition of the bolts before it was torqued ( very tight, tight, loose, very loose, no fixation). This data can be used to analyzed and adjust your maintenance routine which contribute significantly to ensuring a higher standard of safety within airport operations.

What is the initial torque conditions?

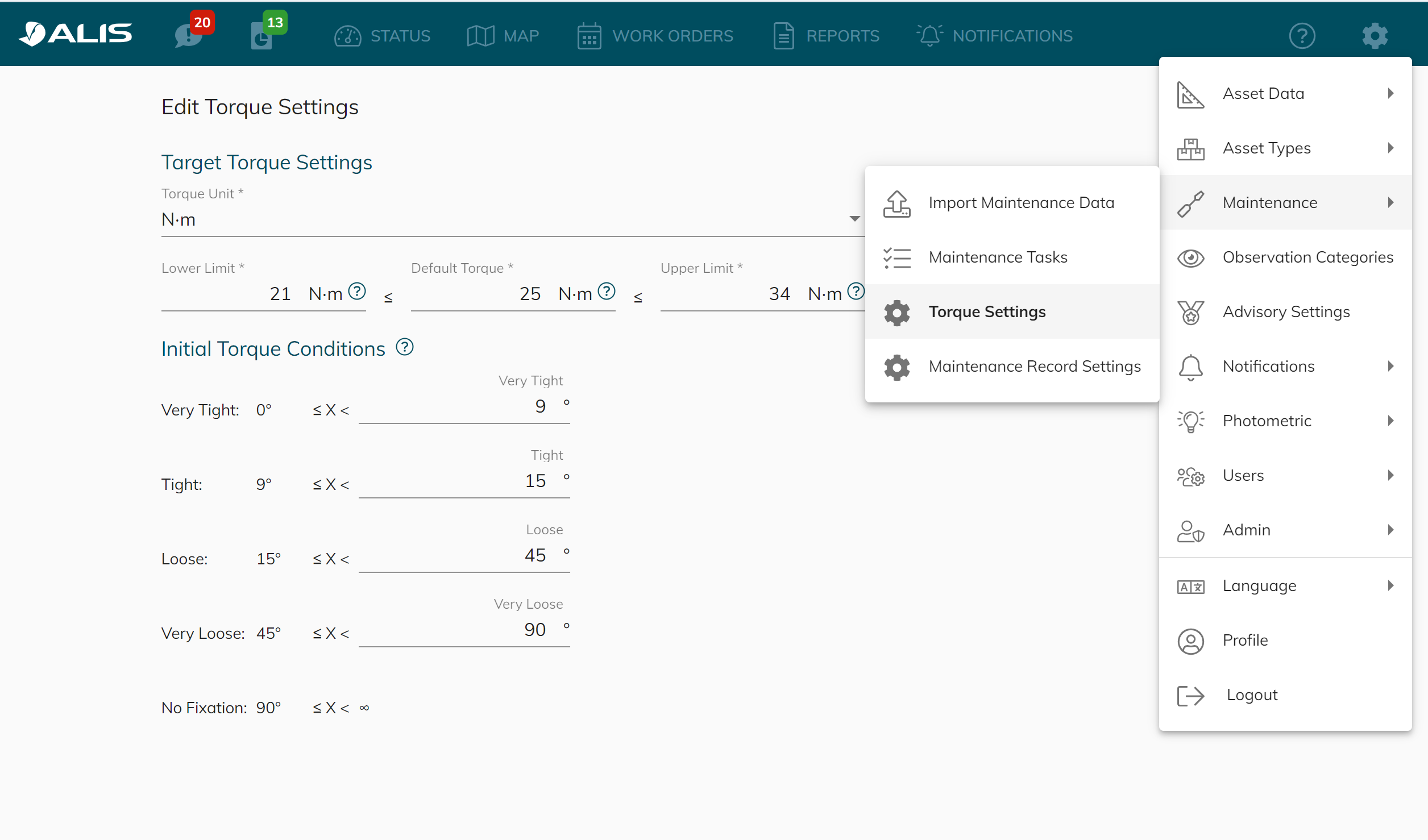

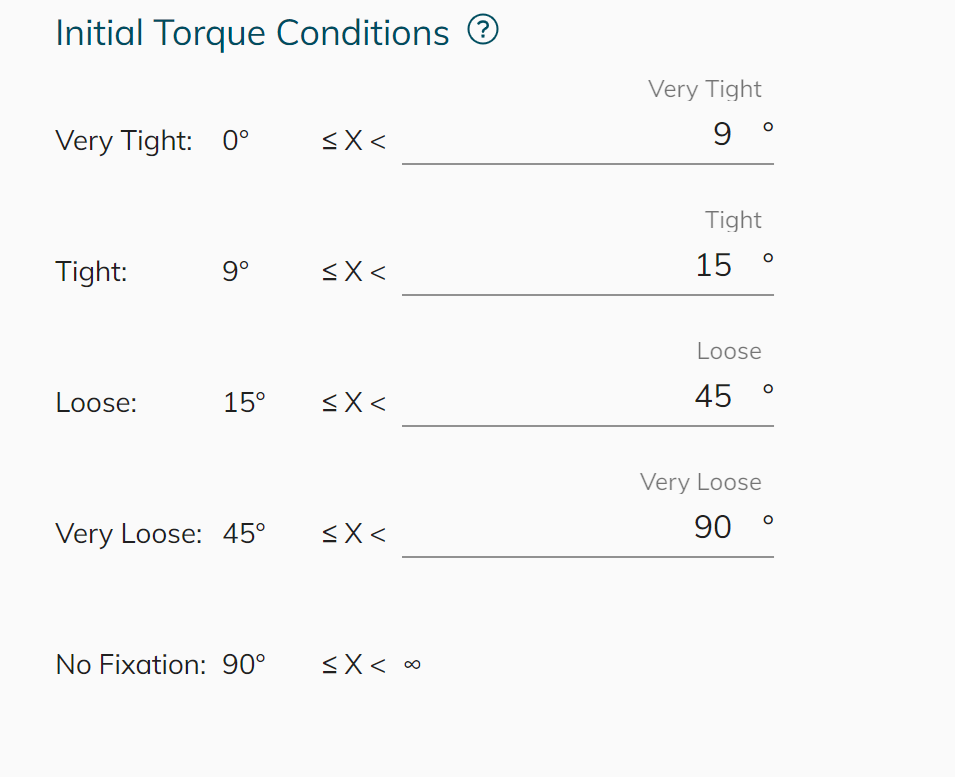

example values, you can find this setting from the ALIS web.

The initial torque conditions uses the angle of rotation to determine whether that bolts were loose, very loose, tight, very tight, or no fixation before the torque maintenance was performed.

The looser the bolt, the higher the angle of rotation will be.

These initial torque conditions setting is adjustable in ALIS web and they can vary from airports to airports.

Table 1 - Understand the meaning of each condition

In this example, we use 25Nm as the target torque.

Category | Description | Angle of rotation |

No fixation | The bolt is barely staying inside the base, this at the point where a person can remove the bolt from the fixture with their bare hands. (The description is approximate, you should already be concerned if your bolt is at the very loose condition). Less than 20% of target torque remains | TBD by experiment |

Very Loose | The bolt is being secured to the base at only 20-40% of the target torque. In this example, it means that the bolt is being fixed to the light with X < 6.25Nm | TBD by experiment |

Loose | The bolt is being secured to the base at 40-85% of the target torque. In this example, it means that the bolt is being fixed to the light between 6.25 ≤ X < 18.5Nm. | TBD by experiment |

Tight | The bolt is being secured to the base at 85-100 % of the target torque. In this example, it means that the bolt is being fixed o the light with 18.75 ≤ X < 25 Nm. | TBD by experiment |

Very Tight | The bolt is being secured to the base at 100-120% (Depending on the High-limit config in the wrench) of the target torque. In this example, it means that the bolt is being fixed to the light with 25 ≤ X < 30Nm. | TBD by experiment |

Now we understand the meaning of each categories, we will now find the which angle correspond to these categories by doing an experiment.

Experiment to determine the initial torque conditions

Equipment and tools

A wrench (ALIS Ingersoll wrench is recommended) to measure the angle of rotation and the target torque values. Best to use with the Extension bar to have as practical results as possible.

A second wrench for tighthening the bolt for creating the different scenerio. You can use any wrench as long as you can measure the torque value from it.

Light fixture (go to the actual field for accurate result)

Steps for determining Angle settings

Make sure you have first set the correct parameters for the Wrench as in. Ingersoll Rand QX Wrench - First time use

Untighten a bolt to the just “hand tight”

Use the Ingersoll rand to record the angle of rotation to reach target torque. This is an indication of your angle for ANGLE FOR "NO FIXATION"

Untighten and retighten a bolt to the just about 20% of your target torque with the manual torque wrench.

Use the Ingersoll rand to record the angle of rotation to reach target torque. This is your max angle for ANGLE FOR "VERY LOOSE"

Untighten and retighten a bolt to the just about 40% of your target torque with the manual torque wrench.

Use the Ingersoll rand to record the angle of rotation to reach target torque. This is your max angle for ANGLE FOR "LOOSE"

Untighten and retighten a bolt to the just about 85% of your target torque with the manual torque wrench.

Use the Ingersoll rand to record the angle of rotation to reach target torque. This is your max angle for ANGLE FOR "TIGHT"

Untighten and retighten a bolt to the just about 120% of your target torque with the manual torque wrench.

Use the Ingersoll rand to record the angle of rotation to reach target torque. This is your max angle for ANGLE FOR "VERY TIGHT"

You can do the above multiple times for each value and taken an average of your different results for a more accurate setting

Example Data collected and result

We read the values and record them in this table.

Target torque: | 25Nm | |

Tighthening torque (Nm) using the blue wrench. | Angle of rotation (degrees) from the Ingersoll wrench | Angle Configuration (degrees) |

0 (using barehand) | 93° | > 65° ANGLE FOR "NO FIXATION" |

4.77 | 68° | < 65° max ANGLE FOR "VERY LOOSE" |

5.76 | 61° | |

10.2 | 47° | < 45° max ANGLE FOR "LOOSE" |

16.86 | 28° | |

22.11 | 17° | < 20° max ANGLE FOR "TIGHT" |

25.27 | 13° | |

31.2 | 7° | < 11° ANGLE FOR "VERY TIGHT" |

35 | 7° | |

Conclusion

This allows us to fill in the “Torque Settings in ALIS as following

Now, it’s your turn to do this experiment on your airport! Before you go, don’t forget to check out the FAQ below.

Extra

The variation in values depends on:

If your airport is using the extension bar or not

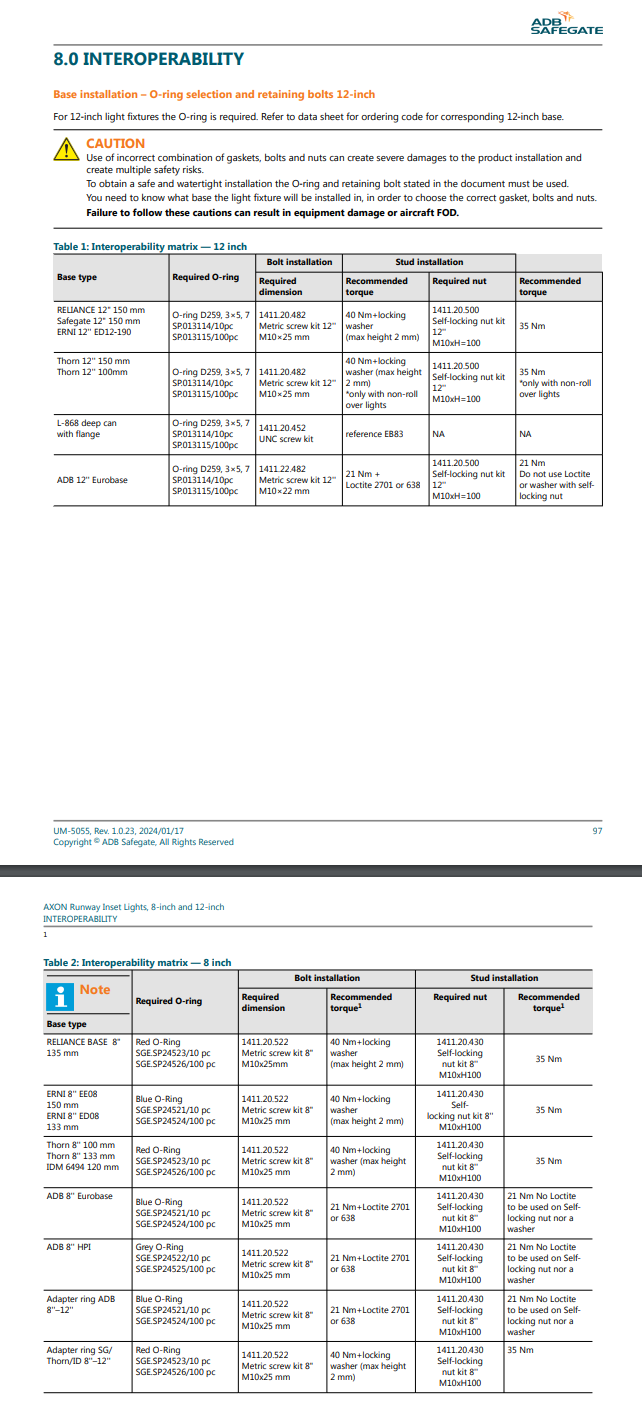

What kind of base is the airport is using

Is the airport using loctite, type of washers, coated bolts etc.

![]() How much “Torque” the Initial Torque condition would be will also be influenced by the factors above.

How much “Torque” the Initial Torque condition would be will also be influenced by the factors above.